Category Archives: Articles

Understanding the Complex RF Interconnect Requirements to Ensure the Highest Performance for Rapidly Advancing Quantum Computing Technologies

Understanding the Complex RF Interconnect Requirements for Quantum Computing Technologies

Understanding the Complex RF Interconnect Requirements for Quantum Computing Technologies

By Dave Slack, Director of Engineering

Originally Published with Microwave Engineering Europe

Quantum computing technology represents the next frontier of computation based on the laws of quantum mechanics. The primary use cases today involve scenarios consisting of a complex problem with many thousands of inputs for applications, including cybersecurity, economic and financial modeling, thermodynamic and aerodynamic modeling, cosmology simulation, and more.

In quantum computing, information is processed using quantum bits, or qubits, instead of classical bits. Unlike the bits that power a classical computing machine, which can only exist in either 0 or 1 state, qubits can exist in multiple states simultaneously, making quantum computers much faster at certain types of computations. This enables quantum computers to efficiently solve complex problems that classical computers cannot solve, saving years of development time and substantial money in engineering design.

Qubits and microwave resonant circuits act similarly; they can be driven from a zero to one state with a microwave signal. Under this condition, the possibility of existing in a one or a zero state varies sinusoidally with time. Like other signals, qubits have a magnitude and phase relationship. In quantum computing, one of the limiting factors is that when the resonator is under this driven condition, it can only be predictable and controlled for a particular time period.

This is due to effects that cause it to lose energy and stop resonating. The limiters are known as the correlation of the qubit. When qubits become de-correlated and are no longer predictable and controlled, it creates computational issues analogous to bit errors in data.

Microwave hardware can feed these resonators and minimize contaminations. In fact, one of the prime limitations is ultra-low noise driving signals for qubits, especially low-phase noise, so a great deal of work has been done in the applications of ultra-low phase noise oscillators and similar technologies. When multiple bits are present, they can be coupled and controlled by driving a signal at a microwave frequency. It can be amplitude and phase modulated to give it specific properties. Aside from the low noise sources of these driving signals in precise modulation schemes, the hardware minimizes that contamination.

The Complexities of Quantum Computing Require Specialized RF and Microwave Cable Assemblies

Quantum states are fragile and must be maintained to prevent qubits from de-correlating. As a result, the correlation and control of qubits are fundamental issues to address in the technology’s development. It boils down to the fact that RF “noise” is introduced from thermal, magnetic, and mechanical sources.

High-performance coaxial cable assemblies (which include both the cable and connectors) are crucial in delivering precise, high-frequency microwave signals to the qubits to change their state and perform operations. Using coaxial cable assemblies in quantum computing also helps mitigate the effects of environmental noise and other sources of signal degradation, allowing for more reliable and precise quantum operations.

These assemblies must meet several requirements to deliver precise and stable signals for controlling qubits, including:

- Low Loss: Low loss is necessary to minimize signal degradation and ensure high-quality signals reach the qubits.

- Low noise: “Noise” means qubits lose their property of superposition, which prevents the quantum computer from working. Therefore, cable assemblies must be shielded to prevent interference and avoid disrupting the quantum information stored in the qubits.

- Stability in Extreme Temperatures: The cable assemblies must maintain stable electrical properties over a wide temperature range to ensure consistent performance in challenging environments.

- High-Frequency Range: The cable assemblies must be capable of operating at high frequencies, typically in the range of several GHz, to enable fast and accurate control of the qubits.

- Immunity to Magnetic Interference: The systems must be immune to electromagnetic interference from other sources to prevent errors in quantum computation.

Low Loss, Low Noise

Successfully achieving low loss and noise comes down to material choices and construction methods. These options will be detailed in the following sections.

Extreme Temperature Conditions

One of the essential requirements for preventing interference is to operate in very low temperatures. Quantum computers must be exceptionally cold to be stable—typically colder than the vacuum of space—with temperatures down to -460 degrees Fahrenheit.

RF cables constructed using a silicon dioxide (SiO2) dielectric are used throughout the microelectronics industry for their exceptional insulating properties and to offer semi-rigid, highly temperature- and radiation-resistant cable solutions. Using the development techniques for creating SiO2 cables and harsh environment aspects as a launch point, the next logical step is to apply materials that are more advantageous to quantum computing applications.

RF cable assemblies are used throughout the entire system, starting at the bottom level where the quantum processor (QPU) is located through different temperature levels and out of the chamber to the control electronics. Two material types fit into this space well and are used at different temperature levels: a 4K down to 4mK NbTi construction, which is a superconducting cable designed to interface directly with the QPU, and a room temp to ~4K CuNi-based semi-rigid construction. Room temperature cables also play a vital role in this operation because phase stability is essential. These cables generally have varying lengths associated with them and cannot introduce any errors in the systems.

Smaller Spaces, Higher Frequencies

Technological advances across quantum computing are leading to more complicated requirements for RF systems that must accommodate higher frequencies inside devices that are constantly getting smaller.

For example, quantum computing requires signal access points close to processors.

Cabling is a challenge because in tight space configurations, traditional semi-rigid solutions have limitations; in very small sizes, they become fragile, making installation difficult as these assemblies are more prone to breakage. Using flexible cables specifically designed to optimize space, bending around tight corners, and connecting to various ports without wasted cable length is quickly becoming the preferred option. Durability and material selection are additional considerations as these cables are twisted around in tiny spaces in the challenging environments of quantum computers.

Reducing Magnetic Interference

Quantum computers transmit RF signals within a magnetic field. Non-magnetic coaxial cables are therefore required in critical areas of the signal path as the presence of any magnetic material in these components may cause interference.

As a result, a non-magnetic or non-metal coaxial cable or connector must be “invisible” to the magnetic field, which requires very low susceptibility and no field distortion. A class of hermetically sealed custom coaxial cabling assemblies addresses this by utilizing advanced manufacturing techniques that ensure zero electric field distortion.

Conclusion

Quantum technology is ushering in an era of significant improvements in computing performance. However, the technology is both incredibly promising and highly complex. To help quantum computers perform to their highest potential, unique RF interconnect solutions will be required. As this technology is in its infancy and rapidly developing, technologists should partner with an interconnect specialist with a wealth of experience in creating solutions that have powered the most innovative products to date in the most extreme conditions possible and can innovate as the technology evolves.

Frequency Matters Podcast: Quantum Computing with Dave Slack

Frequency Matters Podcast: Quantum Computing with Dave Slack

Summary

Gary Lerude of Microwave Journal recently spoke with Dave Slack, Engineering Director at Times Microwave Systems®, on quantum computing. Watch the complete video or read the session notes below.

Session Notes

What is quantum computing?

Quantum computing has been in development for a couple of decades now but it’s really starting to heat up for several reasons. I compare it to classical computing. With classical computing we’re all familiar with we use ones and zeros and binary data. Quantum computing works using the quantum properties of atomic and subatomic matter. It uses those very strange quantum properties and it’s pretty interesting technology.

I tend to look at new technologies like this in a historical context because I find you can look at what has happened and play that forward and get a pretty good understanding of how things are going to play out in the upcoming years. If you look back at the development of classing computing right in 1951, the U.S. Census Bureau took delivery of a machine called Univac. This Univac was room sized, it was sixty thousand pounds, 5,000 vacuum tubes, and it could perform calculation at a massive 1,000 calculations per second. We processed that as a kilohertz. Today we have hundreds of megahertz computing power in our pockets that we’re just carrying around with us so quite a gap has been covered in that period. From 1951 with the vacuum tubes, in the late 50s transistors were introduced; in the 60s and 70s those transistors were integrated into integrated circuits. 1980s microprocessors came along and computers got more and more powerful and they got smaller and smaller and smaller. 1965 a gentleman named Gordon Moore put out Moore’s law, that the transistor density of chips would double every year and that has that has been true from 1965 until about 2010.

In 2010 Moore’s Law started to trail off, meaning that the technology behind classical computing is starting to reach it’s the limits of physics and the limits of economics. To get the computing power that you know many industries need is going to be increasingly less possible with classical computing. Classical computing, as we mentioned earlier, uses very discrete ones and zeros. No ambiguity. It’s either/or, nowhere in the middle. It’s very predictable, it’s very reproducible. Quantum physics uses the properties of quantum, of quantum mechanics, which is the mechanics of matter very, very microscopic scales.

The basic element for computations is called a quantum bit or qubit. Qubit can be it can be a one or a zero, but it actually shouldn’t be thought of as a one and a zero because it can be both which is kind of which is kind of weird when you think about it. And quantum mechanics also use the principle of entanglement, where one qubit can be in a state and it will be coupled with another qubit their states will kind of mimic each other without any physical connection, which is super weird.

When I try to get my head around how can a bit of data be a one and a zero that’s really hard for me to grasp, so I think of it, being a microwave guy, I think of it in terms of noise. I think about that spectrum analyzer with no inputs and you set your filters up and you get noise for down 130, 140 dbm, and you see the randomness, you just see random noise. And you could park a market at any frequency you want to and you’re going to get this range of noise values. You know, they’re going to be all over the place. So you cannot say that if I put a marker at five gigahertz, I am going to measure power X. it’s just not that deterministic like you would expect in a classical computing world. Being a one or a zero, what you’re going to see is a range of numbers and if you capture those numbers over time you can describe them statistically. You will have X probability of measuring Y value every time you sample. It’s about the best you can do. And that’s the way I think of a quantum bit or qubit being a one and a zero. If you’re controlling it and it should be in the one state you know statistically it’s going to tend to be in the one state but it could be in a zero or anywhere in between. It’s only what it is when I measure it is what matters. Quantum computing takes advantage of both of those properties, the superposition properties of the one and the zero and the entanglement properties. The entanglement kind of gives you true parallel processing, so whereas classical computing power increases linearly as a function of computing power, the number of transistors and number of bits, quantum computing increases exponentially with the number of qubits so they can be massively more powerful with every time you add on another bit. They have the ability to be super powerful with a fraction of the energy usage.

So I’m with you so far, that makes sense. I like your analogy of the kind of noise floor on a spectrum analyzer to try to understand the probabilistic nature. If we think about more practical terms, you talked about the power of quantum computing, but what would a quantum computer be able to do?

First of all what they will not do is replace classical computing. We’re always going to have that. That’s always going to be the best tool for many, many calculations. What quantum computing will do is it allows the use of different bits. It uses different algorithms and works totally differently and what it will allow you to do is take problems that have a massive number of inputs and where these inputs are not always discreetly defined they’re more statistical inputs, and it will allow you to process problems like that because that’s the way the machines thinks and works.

The use cases that are seen for this is anything where a large number of complex numbers are involved, like cybersecurity, security, banking security, financial and economic modeling. If you try to get two economists to agree on what the economy is going to do their models are limited in what they can do so the quantum computer is really geared towards that kind of a complex problem with thousands and thousands of inputs into it. Predicting the weather, you can never get two weathermen to agree on what the weather is going to do. It’s super complicated modeling climate change. All these super complex models are where I think quantum computing has a fit.

I think artificial intelligence is just going to explode when it has access to this tool. And the other thing is you know aerodynamic and thermodynamic modeling, especially with hypersonic weapons, that modeling of those thermodynamics and the aerodynamics at those speeds and velocities aren’t well known, so today they’re doing a lot of physical testing to kind of understand. They run models that takes weeks to complete. Having a quantum computer to run those models would be way less physical testing and they could run more models much more quickly would be super valuable.

That makes sense, a lot of power involved there particularly with very complex problems. Now, we hear that there’s a connection between quantum computing and microwave engineering. How is microwave engineering involved in quantum computing?

That’s the question for this audience, I’m sure. So how do we play in this? The qubits, you can think of the qubits as a microwave resonator like an LC tank or something, and you can drive these qubits from a zero state to a one state, to one energy level zero or a one, by driving it with a microwave signal. It’s a resonant and you drive it with a signal at that frequency of resonance and you’re going to change the energy level within that resonator. Under this driven condition the probabilities of being a one or a zero vary sinusoidally with time and it could be controlled too much the way other signal can be controlled. It’s important to know that like other signals, the qubits have magnitude and a phase relationship. They’re complex signals, so it’s very familiar to the microwave community these concepts.

One of the limiting factors in quantum computing is when you have this resonator under this driven condition, it’s kind of predictable and controlled and is only able to be maintained for a certain period of time because with any resonator there’s losses and there’s things affect it that cause it to lose energy and stop resonating. And that’s the limiters here. That is called the correlation of the qubit. When these things become de-correlated they’re no longer predictable, they’re no longer controlled, and that’s analogous to bit errors in data, so you’d have computational issues. The correlation and the control of the qubits is one of the real driving issues behind the technology development. What it really boils down to is the noise comes from thermal noise, it comes from magnetic noise, and it can come from mechanical noise, vibrations, things like that. Microwave hardware that can feed these resonators and minimize these contaminations. In fact, one of the prime limitations is super low noise driving signals for the qubits, especially low phase noise, so a lot of work is going on to ultra low phase noise oscillators and things like that.

The way to have a computer, you need more than one bit so you have two bits or multiple bits; when you have two of these bits they can be coupled together and they can be controlled by this driving signal which is at a microwave frequency, and it can be amplitude and phase modulated to give it certain properties. Both qubits can be modulated separately, and then using the wave properties of the two you can get it to perform in certain ways and the wave properties actually interfere. It’s very analogous to interferometry that antenna and radar people do.

I think of it again in terms of that classic high school demonstration of the two slits and the laser beam and you get the interferometry pattern, you get areas where the two wave patterns can interfere constructively and then others where they interfere destructively. You get kind of high-density probabilities and low density probabilities. You get essentially the ones and zeros and those can be controlled. All of the hardware that’s used to control these qubits and this coupling, I’ll introduce these noises, the thermal, the magnetic, the vibrational noise, so aside from the low noise sources of these driving signals in precise modulation schemes it’s hardware that minimizes that contamination. This is where I think a lot of the microwave community can support.

I think one of the requirements to maintain low noise is to have very low temperatures. Is that correct?

Absolutely. The resonators, the lump constant model is an inductor in parallel with a capacitor. And if you have that you have this perpetual motion machine that just the magnetic flux collapses drives the capacitor which then charges and then discharges and repeat. That would go on forever on paper but in reality there’s losses, these resistive losses, so you get kind of a damp sine wave unless you feedback some of that energy with this driving signal. Being at cryogenic temperatures, below 4 miliKelvin, which is really close to absolute zero, which also astounds me that we can get things that cold, but you minimize resistive losses. It’s virtually zero so you don’t have those losses. The noise floor is less so thermal noise is less. The quantum computing actually wants to happen in a really hard vacuum at super cold temperatures and totally shielded from the Earth’s magnetic field. It’s a very pristine place that these computations want to take place.

You’ve convinced me that there’s a lot of potential here. What’s the actual state of the technology and capability today? I know there’s a lot of research going on, but where are we?

The way I see it, we are in the period before Univac was delivered to its customer. We don’t quite have that Univac machine, that big room-sized monster. The first time commercial quantum computers are going to be quite analogous to that and I think over time they’re going to do what classic computers have done, they’re going to get smaller and faster and more accurate very quickly. I think in the decades that have spanned between then and now, I think that development time frame is going to be a fraction of what it was. I think the next five years are going to be astounding. Next year is going to be a big year and the next ten years is just going to be amazing at where the development is.

Google is spending billions of dollars on this and they have recently just claimed supremacy; they’ve proclaimed there’s a computer problem that Google’s quantum computer has solved in 200 seconds that they claim that IBM Summit machine would take 10,000 years to solve which is an astounding claim. IBM of course disputes this. IBM says that now it would take our Summit computer two and a half days to solve this problem, so by IBM’s own numbers it’s taken a two and a half day solution can now be done in 200 seconds which a thousand to one improvement. And this is on that pre, this is on that lab level computer. So if we can get a thousand time improvement of our quantum Univac , the next five or ten years I mean only the imagination is our limits. I think it’s going to be a really interesting ride and I’m really looking forward to seeing it unfold.

Hypersonic Missiles Demand Unique Coaxial Cable

Frequency Matters Podcast: Hypersonic Weapons with Dave Slack

Frequency Matters Podcast: Hypersonic Weapons with Dave Slack

Summary

Gary Lerude of Microwave Journal recently spoke with Dave Slack, Engineering Director at Times Microwave Systems®, on hypersonic weapons. Watch the complete video or read the session notes below.

Session Notes

Hypersonic weapons have been a hot topic in the news lately. Please give us some background on hypersonics and what all the buzz is about.

A really quick definition of hypersonic is that it describes any speed faster than five times the speed of sound (above Mach 5). The hypersonic weapon systems creating all the buzz today will go faster—about 10, 15, 20, or even 25 times the speed of sound.

Hypersonic technologies are not new; however, they have been around for 70 years or so since the end of World War II. Examples include Sputnik, the Apollo missions, SpaceX rockets, etc. What they all had in common is that they have a ballistic path, a parabolic arc set by the force of gravity and launch velocity. The path is very predictable, and it is easy to determine where the vehicle came from, where it’s going to land, etc., so it’s easy to defend against and countermeasure.

The difference today is that the new generation of hypersonic vehicles is steerable. This makes it challenging to determine precisely where it came from, which is a game changer. The weapon system that is getting the most attention right now is hypersonic glide vehicles. These are initially launched on a parabolic or ballistic arc but can drop down much lower in altitude mid-course and “glide” at a relatively low atmosphere at hypersonic speeds. As a result, they are much more challenging to detect.

Not only are these missiles traveling at hypersonic speeds, but they are also maneuverable. As a result, the time to react could be as little as two-three minutes compared to 45 minutes or an hour with other missile types, so they are very difficult to defend against. Additionally, there are hypersonic cruise missiles, powered vehicles with a scramjet or a supersonic ram jet. That is another game changer because it can travel at much lower altitudes at much longer ranges and is powered, so it’s not just gliding.

Given the physics associated with hypersonic speeds and the extreme environmental conditions, what kind of challenges or emerging technologies have hypersonics created?

The maneuverability factor is the primary issue when it comes to electronics. Every time the missile maneuvers, it loses energy, which is then dissipated as heat. This is in addition to the heat caused by the friction of slipping through the air stream. Dealing with that heat is one of the significant technical challenges.

Smart weapons are also precise and accurate, usually requiring someone on the ground to identify a target, communicate with the weapon, and guide it at hypersonic speeds. These vehicles are surrounded by a plasma envelope, which is why space vehicles lose communications for a few seconds on re-entry because the envelope shields them from communications. Penetrating the plasma envelope to communicate with the weapon and steer it creates another big technological hurdle. This drives the need to evaluate smaller, lighter options that can operate at higher temperatures.

RF microwave technology is used on hypersonic weapons in onboard systems for communication, as well as detection and countermeasures. I expect the RF microwave community will play an increasingly important role in countermeasures.

Do you have a sense of the market evolving over the next few years as research and development turn into actual fielded programs?

The armed services and government development agencies rely on industry to develop these weapons, components, and underlying technologies. As a result, a lot of investment will flood into this space because it is the department of defense’s number one development priority right now and will likely continue to be a top priority for at least the next ten years.

Don’t let supply-chain disruptions knock your projects off schedule – navigate roadblocks and stay on track

Don’t let supply-chain disruptions knock your projects off schedule – navigate roadblocks and stay on track

Originally published in Military Embedded Systems

By David Kiesling

In today’s unusually challenging environment, companies may need to look for workarounds to stay on track regarding supply chain and delivery. Some electronics companies are learning the hard way that supply-chain resilience is a critical qualification for doing business, whether in their own or in their business partners’ and suppliers’ operations. These lessons will change the way organizations consider procurement and production decisions for the future.

Every business – including those that supply the military-electronics arena – is feeling the pain of supply-chain problems these days. Many, in fact, are finding it impossible to run efficiently, meet demand, and deliver on time when necessary parts and materials are stuck in limbo.

Survival of the fittest

The current tight supply-chain situation is having a painful impact on many companies, slowing production as parts, materials, and labor become scarce. Whether you are waiting on products or services like installation and repair, deadline slippage is beyond frustrating. The delays can kill your revenue, cause you to lose loyal customers and new business, and damage your business relationships.

Planning for the long term might sound a bit ambitious when the more immediate problem is that today’s orders are stalled, so let’s start by discussing survival strategies for the current logjam.

Workarounds you can implement now

Decide first if your current suppliers can meet your immediate needs. Can you wait? If delays are seriously impacting your business, consider all your options. Not all products or suppliers are equally prepared to operate through a supply-chain crisis like this. Those with the lowest incidence of backlogs right now either laid the groundwork for resilience before 2020, or they pivoted quickly to prioritize supply-chain agility as the going got tough. The most successful probably did both.

Look around for alternate suppliers if you need to. You can minimize delays by working with the companies that can support your short-term needs more quickly than your existing partners can accommodate.

If you’re lucky enough to be getting what you need, when you need it, from your existing suppliers – consider placing or confirming orders and inventories as early as you can. That way, you won’t get left behind or caught short.

The long game

These challenges will light the way for successful organizations to prioritize resilience to grow and prosper in the future. How can you be better prepared for tomorrow, next month, next year? Survive the present, of course; protect your relationships and reputation as best you can, using the mitigation tactics discussed above. While you’re at it, consider long-term changes that will better position your company for whatever lies ahead.

Find partners with multiple production facilities worldwide; they can often move your work to areas where bottlenecks are less severe so that changing global challenges don’t shut off your supply. Different regions of the world are feeling COVID-19 impacts and shipping snafus at different times, so redundant geographic capabilities can alleviate regional pressures.

For example: Over the past few years, Times Microwave Systems® strategically managed growth, preparing for a situation such as this by opening new manufacturing and warehousing facilities in China, India, and Europe. Moving production closer to customers allowed for shorter delivery routes and created more options for mitigating shifting labor and supply-chain issues. When difficulties arose, it was possible to maintain a steady inventory and supply of the products and services customers relied on.

Decentralized manufacturing capabilities enabled uninterrupted production throughout the pandemic, building inventory needed to meet immediate demand. By continually increasing on-hand stock for standard materials across internal and distributor-serviced warehouses, companies that prepared this way are now better-suited to weather the volatility in raw material costs, thereby resulting in more stable pricing for customers.

Flexibility and versatility should also be considered in business and supplier relationships. A company that offers custom solutions can work with you to develop the most feasible systems at the time. You can thus avoid getting locked into a one-size-fits-all system design that depends upon one source, one material, or one standard product that could be in short supply when you actually need it.

Watch out for false promises

Make sure you are buying genuine products from a reputable company to ensure your system works as it should. Shortages tend to bring counterfeits, fakes, and clones out of the woodwork, as unscrupulous operators look for ways to cash in on a crisis. The performance of your customers’ products depends on reliable product sourcing. Customers that unwittingly buy inferior products sold under false pretenses often pay the price with dismal system performance.

Moving through and forward

Do whatever you have to do to get through this crisis. Be flexible. Build resilience for the future. Work with organizations that are working through the current issues with minimal disruptions. And adjust your approach to qualifying the companies you work with so that you’ll be ready for the next uncertainty.

Adding new high-frequency capabilities to military avionics applications

Adding new high-frequency capabilities to military avionics applications

By Ted Prema

Originally published in Military Embedded Systems

The high-frequency radio frequency (RF) interconnections within military avionics systems are essential components. They must perform repeatably and reliably and meet reduced size, weight, and power (SWaP) requirements. At the same time, the RF coaxial cables and connectors operating in these critical avionics applications have complex electrical, mechanical, and environmental requirements and must remain accessible for maintenance or troubleshooting.

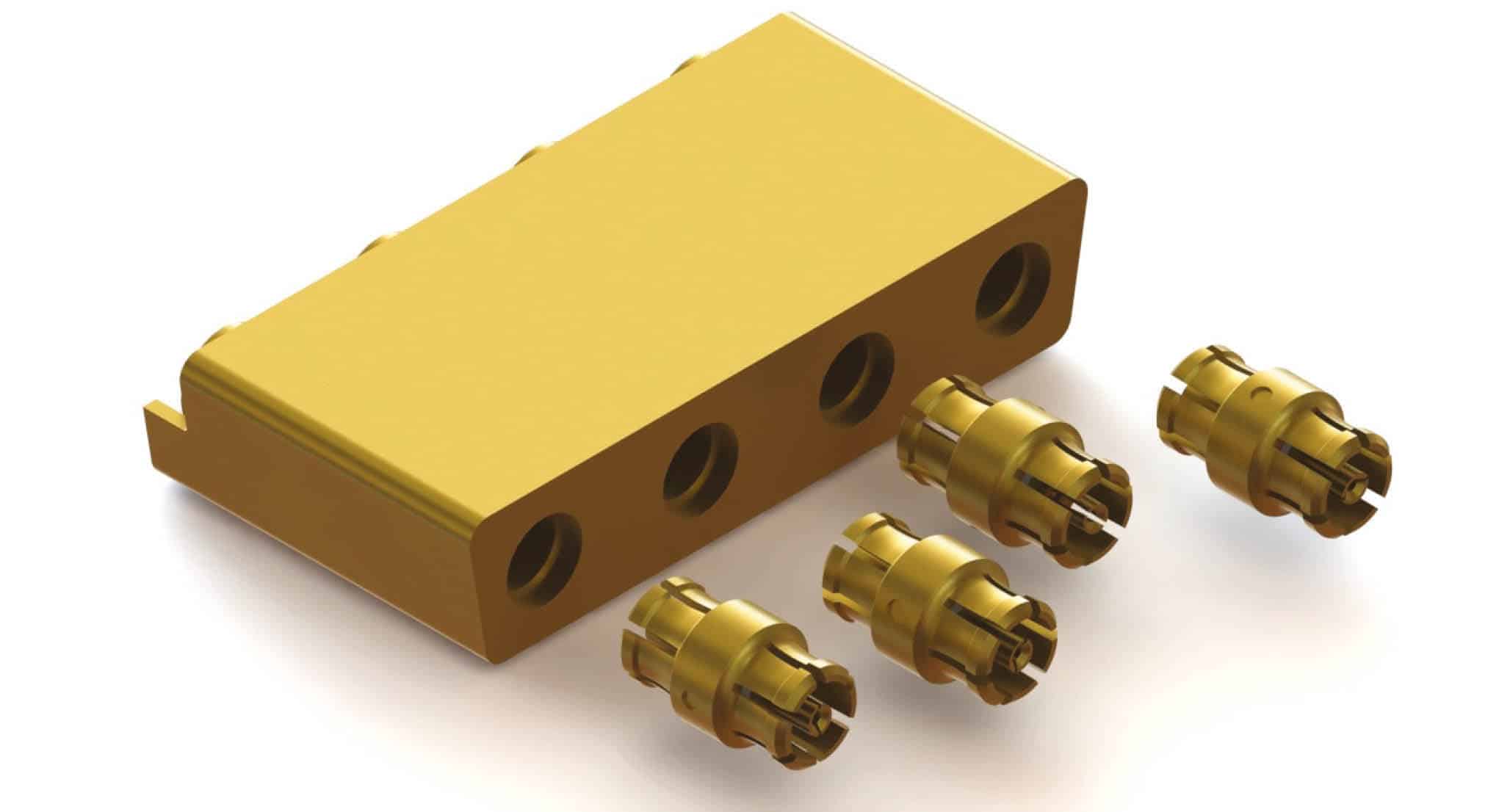

Additionally, fitting these systems into very tight spaces can allow unwanted coupling between RF transmission lines such as coaxial cables. High-density, modular multiport interconnect systems can create a smaller, modular connector assembly. Such multiport connector systems integrate multiple coaxial connector contacts into a single housing for much higher interconnection density than individual coaxial connections.

Frequency requirements are rising

Today’s military avionics technologies, including intelligence, radar, collision avoidance, electronic guidance, navigation, electronic warfare, and communications, require higher frequencies to provide increased bandwidth for a growing number of complex subsystems. Military avionics systems that once operated at frequencies of 12-18 GHz are now extending into the millimeter-wave (mmWave) frequency range of 30 GHz and beyond.

High-frequency RF interconnects for military avionics systems must retain their predecessors’ lightweight and small form factors to fit the high-density requirements of modern airframes and avionics systems. Driven by reduced SWaP equipment requirements, avionics systems are being mounted within smaller airframes and equipment housings, requiring coaxial assemblies to maintain reliable electrical and mechanical interconnections in tight spaces and under the most severe operating conditions.

Such a compact modular multiport connector system provides smaller, lighter interconnections to support denser, more tightly packed avionics systems. By mating a single multiport connector rather than multiple separate coaxial cable assemblies, the single connector interface provided by multiport shells reduces installation time, can ease system maintenance and testing, and increase reliability.

Expand capabilities within existing infrastructure

Military avionics interconnect systems operate in harsh environments on a wide range of airframes, enduring high-shock and vibration; corrosive effects of fuels, hydraulic fluids, and other chemicals; vacuum-like conditions created by high altitudes; and wide temperature ranges. These military avionics systems must handle these challenging environmental conditions while packing greater functionality into smaller spaces. This requires new coaxial cables and connectors to deliver high signal integrity and reliability.

Critical considerations for RF interconnects for challenging avionics and airframe applications include:

- Lightweight: Weight reduction is critical to increasing fuel efficiency. Today’s frequency band requirements are also becoming more complex, creating the need for additional lightweight, small, high-precision RF solutions.

- High density: The increasing number of antennas in military avionics applications creates the need for more electronic boxes and their connections. Furthermore, new high-density solutions are required as frequencies increase and interconnect dimensions decrease to accommodate shorter wavelengths.

- Shock and vibration: When a connector attached to an antenna vibrates, as it will in flight, microphonic noise can impact the connection. This can cause interference in the signal transmission and errors for the RF system. Minimizing space between the cables and connectors is necessary for the interconnect system to survive the high vibration. Furthermore, this microphonic noise wears out the plating on the pins. Use of spring-loaded interfaces can all but eliminate this for both electrical and mechanical improvements.

- Temperature: Higher altitudes, speeds, and frequencies result in higher temperature requirements, making materials considerations more complex.

- Maintenance and access: Antennas mounted on the aircraft’s exterior are routinely damaged, and expedited repair of those antennas is essential. However, antennas are often difficult to access in many avionics systems, making maintenance and replacement very complicated and time-consuming.

Multiport shells such as the M8® multiport connection system are constructed from lightweight aluminum and have advanced reach/ROHS-compliant conductive platings tested to the most severe corrosion resistance requirements. (ROHS is a directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment.) The new contact designated M8M works up to 40 GHz and meets the needs of new high-frequency applications. The M8 multiport system has a a shielded structure to meet the electromagnetic interference and electromagnetic compatibility (EMI/EMC) requirements of densely packed military and civil avionics systems. The design also enables blind-mating interconnections. A spring-loaded design aims the parts for use in the harsh, high-vibration, environments typically found in military avionics applications. These parts are in service on a variety of U.S. and allied military aircraft from SIGINT/ELINT [signals intelligence/electronic intelligence] platforms to fast fighter jets.

Advanced military avionics electronics applications must accommodate extremely restricted space constraints and rising operating frequencies. A military avionics wireless system’s range that once operated between 12 and 18 GHz is now extending into the millimeter-wave (mmWave) frequency range of 30 GHz and beyond. High-frequency RF interconnects for military avionics systems must retain their predecessors’ light weight and small form factors to fit the high-density requirements of modern airframes and avionics systems.

Phase-Stable Cables and the Challenges of Space

New RF Interconnect Solutions Power Mission-Critical 5G Networks

New Multiport Contacts Add High-Frequency Capabilities to UAS Applications

Cables Keep Radar Antennas Tracking

Rapidly Advancing Technologies Create New Challenges for RF Test and Measurement

Rapidly Advancing Technologies Create New Challenges for RF Test and Measurement

Originally Published in Microwave Product Digest

Powering high-performance, ultrareliable RF systems in military electronics

New Connector Design Addresses Significant SMP Shortcomings

New Connector Design Addresses Significant SMP Shortcomings

Originally Published in Connector Supplier

RF cables and connectors for avionics balance size, materials

Making Connections in Ruggedized UAVs

Making Connections in Ruggedized UAVs

By Dave Murray

Originally Published in Microwaves&RF

Military unmanned aerial vehicles (UAVs) are growing in numbers and complexity, taking on more advanced payloads with multiple sensors. Modern battlefield UAVs do everything that human-piloted air vehicles and their avionics systems once did, including electronic warfare (EW), signal intelligence (SIGINT), and surveillance, often flying at high altitudes and high speeds. Many military UAVs are designed with modular configurations to install different subsystems for each mission to optimize results.

Whether in standard or modular formats, military UAVs rely strongly on their RF/microwave interconnections to keep all systems linked, including from the UAV to the ground through demanding operating conditions. Specifying RF connectors, cables, and cable assemblies for military UAVs, especially as they increase their use of mmWave frequencies, requires an intelligent balance of many factors to keep all systems connected under all conditions.

Military UAVs vary in size and complexity according to application and mission, with larger, fixed-wing vehicles flying at higher speeds and altitudes compared to smaller, fixed- and rotary-wing vehicles used at lower altitudes in commercial and industrial applications. One of the better-known high-altitude UAVs, the RQ-4 Global Hawk, has flown at altitudes of 60,000 ft. and higher.

SWaP Considerations for UAV Components

Military requirements for size, weight, and power (SWaP) offer excellent guidance for component selection in UAVs because component weight and power consumption translate to a UAV’s operating range. In addition, components such as cables and connectors must fit into tight spaces and still be accessible for maintenance and measurement purposes.

UAVs contain many electronic parts and subsystems that must be interconnected, such as antennas, data recorders, radars, receivers, and transmitters. The cables and connectors provide the pathways for routing data, signals, and power throughout these subsystems. Any interruption in the pathways can be mission-critical, even fatal.

In general, space for components and payload in a UAV is limited, whether for military, commercial, or industrial use. The cables, connectors, and cable assemblies that provide interconnections within a UAV must meet tight space requirements while maintaining high performance and reliability. These interconnections have to satisfy challenging mechanical and electrical requirements within a UAV capable of enduring severe environmental conditions.

Choosing Cables and Interconnects: Where to Begin?

A practical starting point for sorting through coaxial cable interconnects is determining if they will even fit within the airframe. Smaller cables may fit where space is limited, adding little to the total weight of the UAV, but they may lack the performance to meet the electrical requirements of its electronic systems, so mechanical and electrical needs must be balanced.

Ideally, once installed, coaxial interconnections can be readily accessed for testing and maintenance purposes. UAVs with modular sensor systems will require access to interconnections for different modules used within the airframe.

Cable selection requires a balance of the mechanical, electrical, and environmental requirements for a UAV’s systems. Maximum cable diameter and weight are practical starting points when sorting through available cable solutions. The coaxial cable should exhibit low loss across a frequency range of interest, which will depend on the length and diameter of the cable.

The cable’s insertion loss and return loss (VSWR) also will be affected by the choice of connectors and how well the cable assembly and connectors are constructed. Low loss is particularly important for cable assemblies used at higher frequencies since signal power is limited at mmWave frequencies.

In addition to cable diameter and weight, the flexibility of a coaxial cable assembly is essential when determining whether a particular assembly can fit the needs of a UAV’s interconnections. Interconnect flexibility can be gauged in terms of its minimum bend radius, which is a function of a cable’s construction. Minimum bend radius effectively defines the space required for the smallest change in a cable’s direction.

Weathering High-Stress Conditions

High-frequency interconnect cable assemblies for military UAVs face severe conditions while in flight due to changing weather and stresses caused by high-speed operation. Some UAVs developed for high-altitude operation include hypersonic capabilities with speeds reaching Mach 5 and above. These speeds result in high-temperature environments for the UAV’s electronic components and systems, which must operate reliably at these higher temperatures.

Because the interconnections are such critical components, cables and connectors for military-grade UAVs are designed for operating temperatures as high as +300°C and total operating temperature ranges as wide as −65 to +300°C. Even the 300°C limit is being challenged; thus, Times Microwave Systems® (TMS) has been asked to develop materials for its cables and connectors to handle these new challenges.

RF/microwave interconnections in military UAVs, especially those with phased-array antennas, require high phase stability with temperature. Phase-matched cable assemblies are typically used in antenna systems where phase is used as a beamforming and tuning parameter and in multiple-input/multiple-output (MIMO) antennas that combine the contributions of multiple antennas to send and receive high-frequency signals, often with wide modulation bandwidths.

High-altitude (typically 50,000 ft. or more above sea level) UAVs often operate in conditions that expose their components to near-vacuum environments, resulting in moisture-absorption problems when it returns to sea level. This “water in the cable” affects the interconnect amplitude and phase characteristics of the cable’s conductive metals and dielectric insulators and may result in significant degradation and failure of an electronic systems. As a preventative measure, coaxial cables designed for military UAVs, especially those for high-altitude operation, usually include some form of environmental seal against the effects of vacuum-like environments.

Adding Connectors

The mechanical, electrical, and environmental performance levels achieved by a UAV’s coaxial cables also must include its connectors as they contribute to the SWaP levels. Connectors are typically designed for ease of installation and minimal mechanical and electrical performance degradation. For UAV applications, the high-performance levels must be maintained at high shock and vibration levels.

The quality of a coaxial connector’s machined components, as well as performance and reliability, are impacted by how well the connector is attached to the cable and the effectiveness of its locking mechanism in a mated pair of connectors. Connectors can be soldered or crimped to a cable, with soldering the more labor-intensive approach but providing a robust mechanical attachment with little performance degradation over time. An effective plated finish on a coaxial connector also can contribute to reliable and consistent long-term performance.

Due to the modular architecture of some UAVs, some coaxial connectors must endure many mate-demate cycles for changing of function modules within the UAV. In such cases, a connector’s mate-demate lifetime needs to be evaluated along with its mechanical, electrical, and environmental performance parameters to achieve the best fit within a particular UAV. Oftentimes, high-frequency, high-performance blind-mate connectors are used in UAVs for this purpose.

Seeking Solutions

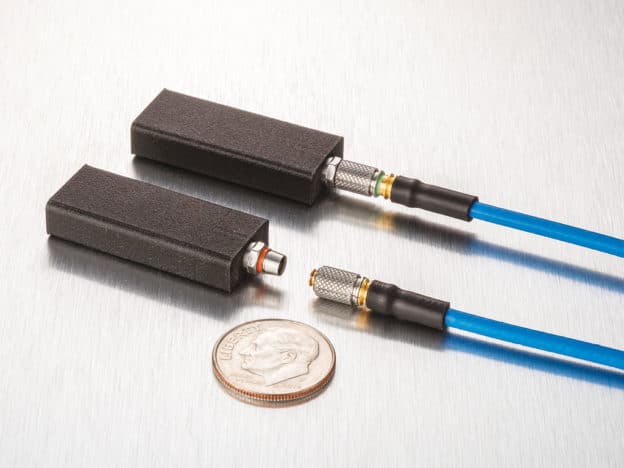

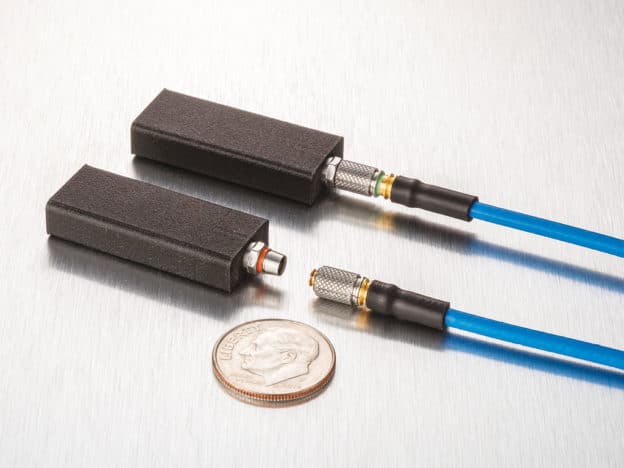

Practical UAV interconnection solutions are typically available as cables or cable assemblies constructed according to precise lengths and designated connectors. For example, TMS’s MILTECH® flexible cable assemblies (Fig. 2) from Times Microwave Systems feature excellent shock and vibration resistance and good phase stability over a wide operating temperature range (−65 to +200°C). They’re manufactured to applicable military standards with tight cable/connector interface control to achieve the hermetic seal needed for high-altitude flight.

The cables are constructed with polytetrafluoroethylene (PTFE) dielectric, a solid silver-plated copper center conductor, and a silver-plated copper shield for protection from electromagnetic interference (EMI). Furthermore, they’re factory-terminated with a variety of coaxial connectors.

To meet the tight space requirements of different UAV systems, MILTECH cables come in various sizes/weights, including 0.130-in. (3.30-mm) diameter cables with 0.650-in. minimum bend radius and 0.175-in. (4.45-mm) diameter cables with 0.875-in. minimum bend radius. The smaller-diameter cables can be terminated with 2.4- or 2.9-mm connectors for use at mmWave frequencies. The cables feature high moisture resistance and vibration resistance according to MIL-STD-202 requirements and high shock resistance per MIL-E-5272 requirements.

For tight UAV fits requiring cables bent close to the connector, TMS’s InstaBend® 047 cable assemblies (Fig. 3) provide low-loss propagation of signals up to 62 GHz in the tightest spaces. To ensure high-quality attachment of connectors to cable, they’re only available as complete assemblies.

An InstaBend 047 cable assembly with an outside diameter of 0.10 in. (2.67 mm) provides a minimum bend radius of 0.3 in. (6.4 mm). Light in weight for UAVs, these cable assemblies weigh only 0.01 lb./ft. (0.02 kg/m) and are available with several different connectors depending on frequency range. They handle temperatures from −60 to +125°C, are shielded to −90 dBc, and rated for voltages to 100 V.

When phase must be tightly controlled, PhaseTrack® cables and cable assemblies developed by Times Microwave Systems are well-suited for that parameter, coming in a variety of diameters with different connectors. A 0.108-in. diameter cable (Fig. 4) features a cutoff frequency of 80 GHz and a minimum bend radius of 0.550 in. The cable is constructed with proprietary TF4® dielectric and doesn’t suffer the phase variations with temperature common to cables with PTFE dielectric.

PhaseTrack cable assemblies fit ground, sea, airborne, and space platforms. They’re available in many versions, including a silicon-dioxide (SiO2) dielectric for applications with temperatures exceeding +1000°C.

Rugged Connectors

Maintaining connections under high shock and vibration levels common to a UAV while being easy to mate requires a coaxial connector with a simple but effective locking mechanism. The TLMP push-on locking connector from Times Microwave Systems (Fig. 5) was designed with the small form factor of the popular SMP push-on connector but with improved mechanical, electrical, and environmental performance.

The TLMP connector, which is usable to 60 GHz, has a unique mechanical design that supports high-pulsed-power, high-voltage applications. Its latching mechanism achieves improved mating retention compared to an SMP connector even in the high shock and vibration environments of military UAVs. The connector’s slots are entirely covered with its mating part for improved EMI and EMC performance compared to an SMP connector. Connections must maintain high EMI and low levels of signal leakage to prevent an adversary from identifying a military drone in flight.

For UAV interconnect applications that don’t require a hermetic seal or enhanced phase stability, Times Microwave Systems’ LMR® and TCA cables and cable assemblies can be practical options. LMR cable assemblies provide flexibility to enable tight fits while LMR LW cables feature an aluminum braid shield for effective shielding in low-weight cable assemblies usable through 8 GHz. TCA cables and connectors have long served commercial avionics systems as flexible interconnect solutions, offering a combination of light weight and durability through 5 GHz and higher.