RF Interconnects for 5G Infrastructure and Applications

By Tony Fedor and Kevin Moyher, Times Microwave Systems

Originally published in Microwave Product Digest

From a practical standpoint, actual 5G infrastructure will be a combination of 4G/ LTE, WiFi and 5GNR. The new mmWave frequencies used in Massive MIMO antennas (5GNR) are getting a lot of hype, and rightfully so. Much effort has gone into the elimination of coaxial cable at these frequencies through the use of fiber, antennas with integrated radios and board level interconnects. With all this, one might think that the demand for coaxial cable would be waning. However, that is far from the case. 5G is likely to drive the largest uptick in demand for coaxial cable that we’ve ever seen.

The interconnect requirements at mmWave are completely different than what we see at traditional telecom frequencies of sub 6 GHz. Whereas, coaxial cable used in traditional telecom infrastructure is often heavy and stiff with bulky interfaces that were optimized for ruggedness, power handling and PIM performance, mm e a whole different animal.

mmWave cables and assemblies are much smaller in diameter due to the limitations of cut-off frequency. In their un-armored state, they are also much more flexible since the corrugated copper sheaths commonly used in lower frequency interconnects will not support the impedance uniformity requirements of mmWave interconnects. This highlights probably the most important characteristic of mmWave/high frequency coaxial cables, very tight impedance uniformity. These high frequency cables also need to be able to maintain their impedance uniformity with bending and flexure. Primarily, this requires the inner conductor to stay completely centered and the outer conductor to keep its shape and diameter. From a practical standpoint, these mmWave assemblies must also be designed in such a way as to allow for termination methods that will provide for impedance uniformity through the cable-connector transition.

Beam forming which was common in many 4G/LTE antennas is pretty much universal in the Massive MIMO 5GNR antennas. In some cases, these antennas drive the need for jumper cables which are phase stable with temperature and possibly flexure as well. Phase stability with flexure can be addressed by using denser dielectrics such as solid PTFE or polyethylene. However, phase stability with temperature is typically the more common as well as the more challenging requirement. The plastics and metals used within a cable have different coefficients of thermal expansion. In some cases, the metals and plastics within a cable, complement each other in terms a phase stability. Interestingly, the time proven process of using expanded PTFE tapes to build dielectrics having very uniform impedances through the use of material uniformity, tape thicknesses and density, application angle and tensions, runs into a brick wall when it comes to phase stability at room temperature. PTFE has what’s called a phase knee at room temperature. This is something that could fairly easily be designed out of a system if all of the cables/feeds within a group or harness tracked together at the same temperature.

However, once again, we look at things from a practical perspective. All of the cables in a group will not be exposed to the same convection cooling and cables that are covered by other cables, will run warmer. Many years of experimentation with plastic compounds have resulted in a compound which has a very good temperature range, linear phase performance throughout its temperature range as good loss characteristics.

At first glance, it might not be obvious just how vast the requirements for RF interconnects in 5G have become. The requirements range from very simple sensor, machine-to-machine and WiFi applications and infrastructure where the frequencies and overall requirements are relatively low, to infrastructure and applications requiring high frequency performance, phase stability and performance with extreme flexure. Interestingly, we’re likely to see some of the most demanding requirements coming from the application side for things such as IP-68 sealing, extreme flexure, extreme temperature, reliability, etc.

High Frequency Interconnects

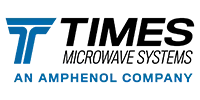

When it comes to high frequency interconnects, you will have to consider the cut-off frequency of a particular core or interface diameter. Attenuation and overall insertion loss will always be a critical consideration at high frequency so in most cases, you’ll be looking for the largest cable that you can get away with, without exceeding the cut-off frequency. See the comparison between maximum frequency (a little shy of cut-off) and cable diameter (Figure 1). The diameter represented is overall diameter of the jacket figuring a thin FEP jacket, round wire braid and thin outer conductor. So, take the 0.130” diameter cable in the table below. It will cut-off just a little above 50GHz so this is roughly the largest cable capable of operating at 50GHz. Following through, the 0.160” diameter cable would be the largest cable capable of 40GHz and the 0.300” diameter cable would be the largest at 18 GHz.

When it comes to high frequency interconnects, you will have to consider the cut-off frequency of a particular core or interface diameter. Attenuation and overall insertion loss will always be a critical consideration at high frequency so in most cases, you’ll be looking for the largest cable that you can get away with, without exceeding the cut-off frequency. See the comparison between maximum frequency (a little shy of cut-off) and cable diameter (Figure 1). The diameter represented is overall diameter of the jacket figuring a thin FEP jacket, round wire braid and thin outer conductor. So, take the 0.130” diameter cable in the table below. It will cut-off just a little above 50GHz so this is roughly the largest cable capable of operating at 50GHz. Following through, the 0.160” diameter cable would be the largest cable capable of 40GHz and the 0.300” diameter cable would be the largest at 18 GHz.

Cable core size will be the most important factor in determining the attenuation of a microwave cable. However, there are a handful of things that can be done to optimize loss. At high frequency, the dielectric material plays a large role in determining the attenuation of the cable:

α = k1 √F + k2 F

k1 = resistive loss constant k2 = dielectric loss constant

Since the dielectric plays such a large role, a small increase in the velocity of propagation (Vp) can have a measurable impact.

In a coaxial cable, the RF signal travels through the skin of the conductors. This is known as the Skin Effect. As frequency increases, the depth to which the signal penetrates the conductors becomes shallower. So much so, that at 50 GHz, the skin depth is only about 11 micro inches. With such a shallow skin depth, silver plated conductors can be used with confidence that the signal will remain within the silver. This both provides for better conductivity over copper and eliminates any concern for copper oxide in the electrical path.

Lastly, since return loss/VSWR will result in mismatch loss which will contribute to the overall attenuation of the cable, minimizing return loss becomes both extremely important at high frequency and more challenging. A coaxial cable which may seem like an efficient RF interconnect at low frequency (VSWR approaching 1.00:1) may look completely different at high frequency due to the much shorter wavelengths involved causing the signal to potentially come in contact with a much greater number of impedance dis-uniformities. The impedance of the cable really boils down to three simple variables, the outer diameter of the center conductor (d), the inner diameter of the outer conductor (D) and the velocity of propagation (Vp) of the dielectric material used. When understanding this relationship, one can see how a semi-rigid tube might be the best choice for a high frequency interconnect (and it often is). However, a stiff semi-rigid tube is just not practical for most applications. The challenge is creating a flexible cable which will approach the impedance uniformity of a semi-rigid tube, in both a static and dynamic state.

Lastly, since return loss/VSWR will result in mismatch loss which will contribute to the overall attenuation of the cable, minimizing return loss becomes both extremely important at high frequency and more challenging. A coaxial cable which may seem like an efficient RF interconnect at low frequency (VSWR approaching 1.00:1) may look completely different at high frequency due to the much shorter wavelengths involved causing the signal to potentially come in contact with a much greater number of impedance dis-uniformities. The impedance of the cable really boils down to three simple variables, the outer diameter of the center conductor (d), the inner diameter of the outer conductor (D) and the velocity of propagation (Vp) of the dielectric material used. When understanding this relationship, one can see how a semi-rigid tube might be the best choice for a high frequency interconnect (and it often is). However, a stiff semi-rigid tube is just not practical for most applications. The challenge is creating a flexible cable which will approach the impedance uniformity of a semi-rigid tube, in both a static and dynamic state.

Times Microwave Systems MaxGain® cables get just about as close as you can get to achieving absolute impedance uniformity and amplitude stability in a flexible microwave cable. This is achieved by serving silver plated copper flat ribbons over the dielectric in a very controlled manner to basically create a rugged low loss flexible microwave cable that performs like a semi-rigid tube in terms of return loss.

Phase Stable Interconnects

Many RF systems offer traditional PTFE dielectric core cables for their RF interconnects. These cables offer a low dissipation factor dielectric material, which yields excellent broadband high frequency RF performance. One drawback of this material is the inherent phase change that occurs at room temperature. This phase change, sometimes referenced as a “PTFE knee,” is steep enough to cause significant phase changes between cables, that are only a degree apart in temperature. This change in phase can exhibit a degradation in performance of many phased array antenna systems.

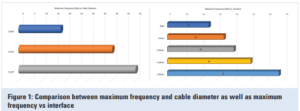

For phase critical applications, the Times Microwave Systems PhaseTrack® series of RF cables offer an excellent interconnect solution. With the use of its proprietary TF4™ fluoropolymer dielectric material, the typical phase change knee is virtually eliminated. Figure 2 compares the phase performance of a traditional PTFE core cable to the PhaseTrack® series of cables.

For phase critical applications, the Times Microwave Systems PhaseTrack® series of RF cables offer an excellent interconnect solution. With the use of its proprietary TF4™ fluoropolymer dielectric material, the typical phase change knee is virtually eliminated. Figure 2 compares the phase performance of a traditional PTFE core cable to the PhaseTrack® series of cables.

As can be seen by the graph, traditional PTFE core RF interconnects will exhibit a phase change of approximately 500 ppm (parts per million) from 50 degrees F to 70 degrees F. Within this same temperature range, the TF4™ dielectric used in the PhaseTrack® cables exhibits a 50 ppm change. To relate this phase change to a length of cable, the TF-4™ dielectric will yield a 4 degree phase change (.006”) across a ten foot cable assembly at 18 GHz.

As can be seen by the graph, traditional PTFE core RF interconnects will exhibit a phase change of approximately 500 ppm (parts per million) from 50 degrees F to 70 degrees F. Within this same temperature range, the TF4™ dielectric used in the PhaseTrack® cables exhibits a 50 ppm change. To relate this phase change to a length of cable, the TF-4™ dielectric will yield a 4 degree phase change (.006”) across a ten foot cable assembly at 18 GHz.

As demands of 5G increase with regards to the high frequency testing of components and systems, phase stable test leads also play an even more critical role. Traditional test leads in many cases may not be sufficient where high reliability testing is required. One of the biggest contributors to measurement inconsistencies is the temperature related drift when testing. With the use of a highly phase stable test leads, the length between calibrations can be reduced dramatically. This is especially useful to any test technician that encounters a variation in temperatures while testing. The Silverline®-XF series is an example of a very flexible highly shielded test lead that was designed for testing of delicate components such as exposed RF circuits with edge launch connectors. These thin, lightweight phase stable cables allows the easy handling of PC boards, without compromising the RF stability and isolation.

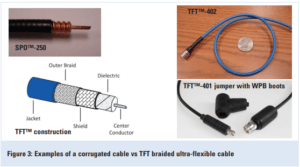

Carriers and Integrators building out 5G infrastructure and densifying existing 4G/LTE infrastructure are requiring coaxial jumpers to be low Passive Intermod (PIM). This is the case regardless of whether we’re talking Macro, oDAS, iDAS or Small Cell. The standard requirement is -153 dBc with two 20 watt carriers. The third harmonic is measured in both a static and dynamic state. Copper corrugated cables such as the outdoor SPO™ and the indoor SPF™ and SPP™ LLPL cables are based on a proven outer conductor construction when dealing with PIM.

Low Passive Intermod (PIM) Interconnects

However, corrugated cables do have limitations in some iDAS and most Small Cell applications due to fragility when forming in very tight spaces. The TFT™ is a braided ultra-flexible cable construction which will provide rock-solid dynamic PIM performance and can almost be tied in a knot and still maintain its VSWR and PIM performance. The TFT™-401 (1/4”) with WPB weather seal boots and terminated with the latest low PIM interfaces 4.3/10.0, NEX 10 (produced under license) or 2.2-5 makes for a real workhorse Small Cell jumper.

Interconnects and Feeders for Ruggedized Applications such as COW’s and COLT’s

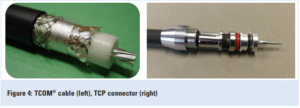

The Times family of TCOM® cables are the most versatile line of low loss coaxial cables on the market. They exhibit all of the qualities of our popular LMR® cable family such as low loss, flexibility and ease of termination and then take it up a couple of notches. TCOM® is extremely rugged and is often the first choice for field deployable applications in both the military and commercial markets. It is also a low PIM cable which will continue to provide rock solid dynamic PIM performance in the area of -160 dBc (measured 3rd harmonic, two 20-watt carriers) with bending, coiling and continuous flexure.

The Times family of TCOM® cables are the most versatile line of low loss coaxial cables on the market. They exhibit all of the qualities of our popular LMR® cable family such as low loss, flexibility and ease of termination and then take it up a couple of notches. TCOM® is extremely rugged and is often the first choice for field deployable applications in both the military and commercial markets. It is also a low PIM cable which will continue to provide rock solid dynamic PIM performance in the area of -160 dBc (measured 3rd harmonic, two 20-watt carriers) with bending, coiling and continuous flexure.

TCOM® is an excellent cable choice for mobile communications platforms such as COWs and COLTs.

The TCOM® cables are built using the same dielectric cores as the LMR® cables. The dielectric is a nitrogen injected closed cell polyethylene foam. This dielectric has been optimized for loss as well as ruggedness. The outer conductor construction is the greatest differentiator between the LMR® and the TCOM® constructions. Whereas the LMR uses a single, bonded metal-polyester shield under the round wire braid, the TCOM® uses a multi-layer shield which allows for direct low resistance outer conductor contact making this construction the most flexible, rugged, low loss, low PIM coaxial cable available. The first layer is composed of a silver-plated copper flat braid which is designed to flex with movement of the cable instead of work hardening which is what would occur with corrugated, tubular or bonded taped outer conductor constructions. The second shield layer is a helically wrapped aluminum-mylar- aluminum tape whose job it is to contain and maintain the flat braids during flexure. Lastly, the helically wrapped tape is covered by a heavy tinned copper flat braid. This triple shield is not only optimized for flexure but also provides greater than -100dB of shielding effectiveness.

The outer braids of these cables are then flooded just prior to jacketing with a material that will basically make the cable self-healing. In the event that the jacket was ever breached, however unlikely it is that this would occur, moisture will not be able to enter the cable itself. The jacket itself is a very strong, pliable, UV resistant polyurethane compound.

It’s not often that you find high shielding effectiveness, and the ability to perform with continuous flexure, in the same cable. Not to mention, excellent dynamic PIM performance, abrasion and chemical resistance and core sizes large enough to satisfy feeder cable lengths in most field deployable applications. We offer these rugged TCOM® constructions with both a solid center conductor (PURDB) and a seven-strand center conductor (Flexstrand DB).

These cables have been placed through rigorous flex testing in just about every conceivable flex configuration including coiling and uncoiling, bend and reverse bending (Tic-Toc), Flex Trac and simulated continuous handling.

As rugged as these cables are, they would not realize their full potential without the TCP connector design. This unique construction which uses materials, plating’s and tolerances which are optimized for low PIM, utilize a BeCu spring collet which has rows of barbs on each finger which grip the cable jacket roughly ¾” behind the electrical contact when the back nut is torqued. This unique construction isolates the bulk of any sideloading force on the cable, from the electrical transition between the cable and the connector.

General Broadband Infrastructure and Applications (IoT, WiFi,, etc.)

In addition to the higher frequency millimeter wave RF components, many 5G systems and applications will also require quality sub 6.0 GHz interconnects. Although lower in frequency, the RF performance of these coaxial cables will play an important role in overall system performance.

The LMR® series of low-loss cables, will allow system designers and integrators a wide range of cable sizes to choose from. These cables utilize a closed cell foamed polyethylene dielectric which when combined with its bonded multi laminate shield and high coverage braid, provides a flexible, highly shielded low-attenuation RF interconnect. The cable sizes will be determined depending on the physical length of cable runs as well as the frequency of operation, and allowable system loss budgets.

When combined with the available cable prep tools and a full range of connector interfaces, the LMR® product family will result in easy and repeatable installations that will yield excellent system performance.

Summary

5G infrastructure and the many new mission critical and IoT applications that will result from the speed, coverage and low latency of 5G, will result in the need for a wide range of coaxial constructions, connector designs and jumper assembly products. We’ve touched on the product families/categories which we feel will play a strong role. We’re fairly certain that 5G will drive requirements in the coming years which we’ve yet to imagine. We’re prepared and excited to see where 5G takes us.

Subscribe to our newsletter!

Interested in receiving email newsletters and other updates from Times? Subscribe now!