Microwave and RF Cable Assemblies: The Neglected System Component

Part 2: Operational Considerations of the Coaxial Assembly

By: David Slack

We’ve discussed some of the typical electrical characteristics of a cable assembly, and some of the environments typically encountered. Other aspects affecting the optimum design of a coaxial cable assembly are covered here.

Power handling

Power handling of an RF or microwave assembly can be separated into two distinct classifications: average power and peak power. Many RF and microwave cable assemblies can handle power levels of several kilowatts when the duty cycle is very low. This would typically be encountered in RADAR applications where a pulsed transmitter is used. It can be assumed, if the duty cycle is low enough, that the average power effects can be effectively ignored. When this is true then the failure modes are arcover due to voltage breakdown and corona formation.

Corona formation is caused when the electric fields present within the cable assembly ionize oxygen that is trapped in microvoids within the assembly. The corona induces noise into the signal that is being propagated and is the precursor to a voltage breakdown.

Corona formation is caused when the electric fields present within the cable assembly ionize oxygen that is trapped in microvoids within the assembly. The corona induces noise into the signal that is being propagated and is the precursor to a voltage breakdown.

Corona is highly charged and is therefore quite conductive. As charge densities increase, in proportion to higher power levels, corona level increases. As these levels are increased further a point is reached where a conductive path is formed between the conductors of the assembly. It is at this point that an arcover condition occurs. An arcover is a destructive condition in that it leaves a carbonized path in its wake that is conductive, and thus a short circuit (or partial short depending on the severity of the arcover) is indelibly left within the cable assembly.

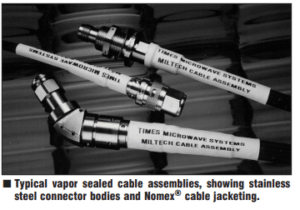

Failures of this nature typically occur at the cable/connector junction. This is normally where the inner and outer conductors are closest together and are least protected.

Through the judicious selection of connector geometries, and through the use of overlapping insulators within the connector, peak power handling capabilities are maximized. When higher duty cycles are required, the average power effects begin to become the limiting factor. This can range from high duty cycle pulsed power to CW power (duty cycle = 100 percent). Average power handling capability is directly related to a cable assembly’s ability to transfer heat to its external environment.

All RF and microwave cable assemblies have an attenuation factor associated with them. As a result of this attenuation, a portion of the power delivered from a source is dissipated within the structure of the cable assembly. Because of the limited ability to transfer heat from internal components, the assembly will undergo a temperature increase. The point where the center conductor temperature approaches the melting point of the dielectric is generally considered the limit of a cable’s average power handling. This limit is approximately +200 degrees C for Teflon® dielectrics and approximately +100 degrees C for Polyethylene dielectrics.

The mechanisms used to transfer heat are conduction, convection and radiation. Conduction is generally the most efficient method of transferring heat from a cable. This would be transferred through the conductors of the cable, into the connectors, and into the mating equipment. This tends to keep the ends of the cable assembly cooler and works best when a large temperature gradient exists between the assembly and the mating equipment.

Convection is the second most efficient method of transferring heat from a cable assembly. This heat transfer is due to movement of air around the assembly and is virtually nonexistent at high altitudes. The third method, radiation, is the primary means of heat transfer at high altitudes. Radiation efficiency is a function of the emmisivity of the outer surfaces of the cable assembly and can be maximized by using black materials with a dull finish.

To maximize average power handling, the selected cable should have the very minimum insertion loss, maximum outer surface area and a high emmisivity jacket. Careful selection of cable routing is of primary importance as well. A cable that performs in a well ventilated area may suffer catastrophic failure when ventilation is restricted. The same holds true when considering the ambient temperature of the cables environment. The temperature gradient between the cable assembly and its surroundings is fundamental to the assembly’s power handling capability.

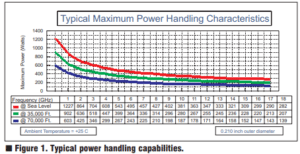

Because of the infinite nature of operating environments, specifying power handling capability of an assembly can be a rather ambiguous process. A system designer should use a generous engineering margin when selecting power cables. Figure 1 shows typical power handling capabilities of a vapor sealed 0.21″ diameter cable with a braided Nomex® jacket.

Because of the infinite nature of operating environments, specifying power handling capability of an assembly can be a rather ambiguous process. A system designer should use a generous engineering margin when selecting power cables. Figure 1 shows typical power handling capabilities of a vapor sealed 0.21″ diameter cable with a braided Nomex® jacket.

Flexibility

Installation, replacement, maintenance activities and other practicalities tend to dictate the use of a flexible cable. Quite often, when harsh environments are being designed for, ruggedization causes flexibility to be compromised. With proper design, this type of trade-off does not have to be made.

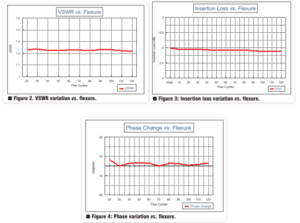

Using inherently rugged dielectric core construction with a combination of strip and braid outer conductor geometries, along with advanced vapor sealing techniques, a cable is produced that will withstand harsh environments while exhibiting a bend radius less than 10 times its outer diameter. Multiple flexing cycles of this cable cause no degradation of the phase, VSWR or insertion loss characteristics of this assembly. Assemblies of this construction, having a 0.210 inch outer diameter, can undergo many wrap/unwrap cycles around a two inch mandrel and will phase track each other to well within 6 degrees at 18 GHz.

Using inherently rugged dielectric core construction with a combination of strip and braid outer conductor geometries, along with advanced vapor sealing techniques, a cable is produced that will withstand harsh environments while exhibiting a bend radius less than 10 times its outer diameter. Multiple flexing cycles of this cable cause no degradation of the phase, VSWR or insertion loss characteristics of this assembly. Assemblies of this construction, having a 0.210 inch outer diameter, can undergo many wrap/unwrap cycles around a two inch mandrel and will phase track each other to well within 6 degrees at 18 GHz.

Figures 2, 3 and 4 show the effects of this flexing on one of these assemblies.

Temperature and altitude extremes

Designing a cable assembly for use in wide temperature extremes involves appropriate material choices, mechanical structures that allow for thermal expansion and contraction, and connector designs that include contact captivation to constrain excessive physical motion. To test assembly performance at temperature and altitude extremes, several tests are commonly employed.

A thermal shock test involves stabilizing an assembly at one temperature extreme then quickly replace it into an environment that is at the other temperature extreme and allow it time to stabilize. This would constitute one cycle of a thermal shock test. Stable, vapor sealed assemblies have been built and tested that endure 5 shock cycles between –62 degrees C and +125 degrees C and maintain phase tracking to within 6 degrees between each cycle as well as after completion of the full test. The VSWR and insertion loss characteristics remained within their specification tolerances as well.

This same assembly has also been evaluated where the temperature extremes are maintained while the assembly is placed in a vacuum simulating altitudes of 70,000 feet. These assemblies operate continuously under these conditions and maintain the electrical performance characteristics of loss, VSWR and phase tracking.

Atmospheric conditions

Aside from the extremes of temperature, altitude and vibration that a cable assembly might see, there are other atmospheric conditions that may affect the assembly. Many systems are required to operate in high humidity levels for long periods of time. This is primarily a sealing issue. If there are even very small leaks in the assembly, moisture will ingress into the conductive path of the assembly. This moisture ingress is exacerbated by changes in altitude and temperature. A common example would be an airplane coming in for a landing, where often condensation forms on the cable assembly as the ambient pressure rises. The increasing pressure tends to force the surface moisture into the cable assembly. Any moisture in the conductive path will seriously degrade the performance of the cable assembly.

Many times, the environment is salt spray or salt fog. This would be typical in installations aboard ships or boats as well as operating areas that are in close proximity to ocean areas. With a salt fog environment, the sealing issue is still fundamental, but there is an added threat of corrosion of the metallic surfaces of the assembly. Careful selection of metals and metal finishes is critical when dealing with corrosive atmospheres. A prudent corrosion control program ensuring high quality

plating and finishes on all components of the cable assembly is needed.

Installability and maintainability

Oftentimes, when an RF assembly is optimized electrically, it is rendered quite fragile mechanically. A high performance coaxial assembly is more valuable if it can be easily installed and still perform to its design parameters. In addition, an assembly should survive maintenance to surrounding equipment as well. Often a coax is installed into a bundle of other cables and forgotten. When other activities take place, the bundle can be crushed, stepped on, have equipment dropped on it, even have hydraulic fluid or gasoline spilled on it. Once an assembly is installed, and other structures installed around it, making it quite inconvenient (and expensive) to replace it.

To ensure that a cable assembly can be adequately clamped in place a clamping pressure test should be performed. A typical clamping pressure test is to place a portion of the cable into a fixture that will place a 50 psi force around the circumference of a two inch length of the cable.

The electrical parameters of the assembly are monitored while this force is maintained for several minutes. Any degradation of the electrical characteristics would indicate potential problems after the assembly is installed

Tensile and torque tests are also important indicators when predicting a cable’s long term survivability. When a cable is installed as part of a system, routine maintenance is usually required. Sometimes this involves removing the system hardware that mates to the coaxial assembly while leaving the coax in place. Too often during installation, the connector ends are subjected to high pulling and twisting forces. While still meeting the other requirements noted earlier, 0.210 inch O.D. cable assemblies were built and tested to withstand greater than 55 inch ounces of torque and 20 pounds of axial force on the connector end without any degradation of electrical performance.

Whenever a cable harness is in an area where maintenance, or other work, is being performed, the assemblies are in danger of having equipment or heavy tools placed on them. To ensure that the specified cable will resist damage in this type of situation, a measure of crush resistance should be performed. For this test, the assembly is placed on a flat metal plate and a ¼-inch-square bar is placed perpendicular to the longitudinal axis of the cable. The electrical performance is monitored on a network analyzer while a 50 lb. weight is placed on the square bar. The assembly should undergo no significant degradation of the electrical characteristics when this weight is maintained for several minutes. Contrary to popular opinion, optimizing a cable assembly’s performance in certain areas does not necessarily mean a significant degradation in other areas. By using quality materials, optimizing a cable assembly for long life performance in a rugged environment involves choosing the right conductors, platings, dielectric materials and connector construction. Building the components and assembling the cable assembly using stringent process control and exacting manufacturing methods results in achieving the highest standards of performance possible. An RF or microwave cable assembly is an inherent part of the system and, when built properly, can contribute to extremely high Mean Time Between Failure (MTBF) values. This article has illustrated how important it is to specify all of the appropriate requirements when choosing an RF or microwave coaxial cable assembly.

Subscribe to our newsletter!

Interested in receiving email newsletters and other updates from Times? Subscribe now!