Cable Performance

Microwave and RF Cable Assemblies: The Neglected System Component

Part 1: Electrical and Mechanical Aspects of the Coaxial Assembly

By David Slack

Times Microwave Systems

Modern RF and microwave systems must perform at unprecedented levels of precision in harsh physical environments. These environments include extended immersion in deicing chemicals, hydraulic fluids, fuels, high altitudes, high vibration and wide-ranging temperature extremes.

Microwave cabling hardware is often treated as an ancillary issue instead of the integral part of the system that it is. A microwave cable assembly is not “just a wire.” It is a passive, TEM mode, microwave component and an integral part of a microwave system. When a microwave or RF system is being designed to operate in a harsh environment, a little advance care given to cable selection will pay significant dividends over the operating life of the system.

Microwave cabling hardware is often treated as an ancillary issue instead of the integral part of the system that it is. A microwave cable assembly is not “just a wire.” It is a passive, TEM mode, microwave component and an integral part of a microwave system. When a microwave or RF system is being designed to operate in a harsh environment, a little advance care given to cable selection will pay significant dividends over the operating life of the system.

This article will discuss the various critical characteristics for RF and microwave cable assemblies and how optimizing some characteristics can tend to degrade other characteristics. This can involve a tradeoff process that, if done haphazardly, can leave your system with some unacceptable vulnerabilities. With proper design, and through the use of sophisticated manufacturing techniques, a microwave cable assembly extremely resistant to the most severe physical tortures can be produced. To support this assertion, the actual performance levels achieved are presented using data taken from a cable assembly recently developed to take all of the noted “operational and environmental hazards” into account. In other areas, data corresponding to “what can go wrong, and why” is presented to illustrate those subjects more fully.

This is the first part of a two-part article. The first half of the discussion will focus on the electrical and mechanical issues that are inherent in a coaxial cable assembly. The second half of the article, which will be published in the January/February 1998 issue of Applied Microwave & Wireless, will focus on the operational environment of a coaxial assembly. It will discuss the things that can happen to a cable assembly once it is installed out in the field.

Optimizing assemblies against hazards

A microwave cable assembly, when designed to be subjected to a particular mechanical or environmental hazard, can be optimized quite effectively for this single hazard. When multiple threats jeopardize the assembly, the optimization becomes a more complicated process.

One example of this is the case of a cable that is desired to have high crush strength. There are several commonly employed methods that will accomplish this goal. A cable design could make use of a solid metal tube as its outer conductor. This type of construction provides excellent crush resistance but is relatively inflexible and is limited in minimum bend radius as well as the number of times that it can be bent.

To achieve a cable that can be pulled into tight radii or repeatedly flexed, a flexible structure must be used as an outer conductor. This structure, typically constructed of braided copper wire, does not offer nearly the crush resistance that the solid tube offers. Depending on the braid construction, as well as several other parameters, a range of crush resistance can be achieved, each having its own set of trade-offs.

Every mechanical and electrical characteristic of a flexible coaxial cable assembly can be optimized, or compromised, in a similar manner. An experienced cable designer, employing state of-the-art manufacturing methods and stringent process control, can optimize all of these essential attributes so that a single cable assembly can withstand even the most rigorous test and qualification regimens.

Insertion loss and VSWR

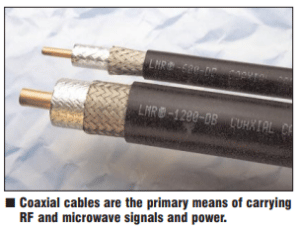

Probably the most widely recognized tests performed on coaxial assemblies are insertion loss and a measurement of the voltage standing wave ratio (VSWR). A typical presentation of insertion loss and VSWR testing results is shown in Figure 1.

Probably the most widely recognized tests performed on coaxial assemblies are insertion loss and a measurement of the voltage standing wave ratio (VSWR). A typical presentation of insertion loss and VSWR testing results is shown in Figure 1.

A 50 W cable assembly, installed into a 50 W system with absolutely no impedance discontinuities, will have a VSWR of 1:1. None of the power that is delivered to this component is reflected back to its source. The VSWR of a cable assembly is presented as the ratio of [1+ (Reflection Coefficient)] divided by [1 – (Reflection Coefficient)], normalized to one. With no reflections, the reflection coefficient would be zero, and the ideal 1:1 ratio (noted earlier) is obtained. Typical VSWRs are in the 1.3:1 to 1.4:1 range.

As a practical matter, all coaxial assemblies have impedance discontinuities associated with them. These imperfections can be generally classified in three categories: line size transitions within the connectors; periodic discontinuities within the cable; and single event discontinuities within the cable.

Assuming a high-quality cable is used, the predominant contributor to the VSWR of a cable assembly on a short assembly is the connector termination. On a longer assembly, the two connectors are isolated from each other by the attenuation of the cable.

A connector has two very important functions. First, it must physically hold the cable assembly in its proper location. If this is not adequately accomplished, the electrical performance will be intermittent at best, or will cease to function at worst.

Second, the connector must electrically couple the transmission line sizes of the equipment to which it is mating with the line size of the cable. Accomplishing this line size transition at low frequencies is a relatively simple matter of mechanical geometry. At RF and microwave frequencies, changes in geometry must be carefully designed, giving full consideration not only to the mechanical elements but also to the electromagnetic issues.

Improperly compensated geometry changes will exhibit very poor VSWR characteristics. In previous eras, this design was considered a “black art,” and trial and error was a key component of high performance connector design. In order to keep design times short and maintain today’s performance levels, sophisticated computer models take on a vital role in the design and manufacture of the connectors.

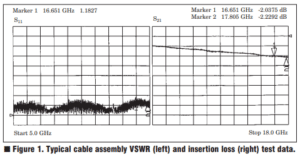

Just as important as the connector design are the techniques employed when installing these connectors onto a cable to form a coaxial cable assembly. Diligent process control and the highest standards of quality assurance are required. Figure 3 illustrates typical VSWR performance due to an improperly designed or installed connector.

Just as important as the connector design are the techniques employed when installing these connectors onto a cable to form a coaxial cable assembly. Diligent process control and the highest standards of quality assurance are required. Figure 3 illustrates typical VSWR performance due to an improperly designed or installed connector.

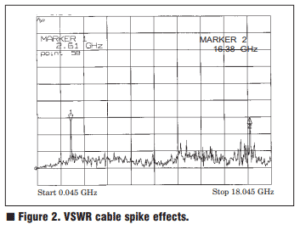

Consistency within the cable is a key element when striving for optimum VSWR performance. One small discontinuity will produce a small, unmeasurable reflection. But when there are a series of periodic discontinuities, many of these small reflections will add at a frequency whose wavelength is an integral number of half wavelengths. This can cause a sharp VSWR spike at a fundamental frequency. In severe cases, there can be VSWR spikes at frequencies that are harmonically related as well.

Figure 2 illustrates the effects on VSWR of the phenomenon discussed here. Single event impedance discontinuities large enough to cause high VSWR are typically caused by dents in the cable from some type of mechanical mishap, such as closing a cable in an equipment cabinet, stepping on it, or rolling over it with a wheeled cart or vehicle.

Insertion loss is the other of the two most common cable parameters. The primary purpose of a coaxial cable assembly is to transmit power from a source to a load. Insertion loss is simply a measure of the power lost in the cable assembly before it reaches the load, typically presented in decibels (dB). Insertion loss is approximately inversely related to the diameter of a cable. For any given cable construction, a larger diameter cable is required to reduce the insertion loss.

There are two general components contributing to the attenuation of a cable. These are the metals used in construction of the conductors and the properties of the dielectric core.

Attenuation is the sum of the conductor properties times the square root of the frequency plus the dielectric properties times the frequency. As the signal frequency is increased, the attenuation component contributed by dielectric will increase faster than the attenuation component contributed by conductors. It is for this reason that it is important to use the highest quality of dielectric materials available to optimize performance at high frequencies.

To provide a cable assembly that can function in adverse environments, exhibit low insertion loss properties and be of reasonable size and weight, high quality metals must be used for the conductor constructions. These metals are typically silver plated and have a mirror- smooth finish. These materials are then applied using sophisticated techniques that allow them to remain both flexible and strong.

To provide a cable assembly that can function in adverse environments, exhibit low insertion loss properties and be of reasonable size and weight, high quality metals must be used for the conductor constructions. These metals are typically silver plated and have a mirror- smooth finish. These materials are then applied using sophisticated techniques that allow them to remain both flexible and strong.

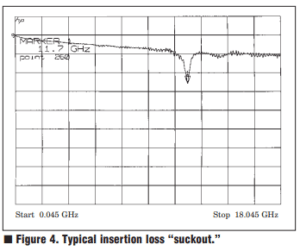

A side issue relating to insertion loss is insertion loss uniformity. There are three causes of insertion loss discontinuities, or “suckouts.” The first of these is improperly mated connectors interfaces due to improper torquing or side loading. The connector interface must maintain equal contact through the full 360 degrees of its mating interface. Second, VSWR causes return loss, which results in power being returned to the source. Therefore, less power is being delivered to the load. When the VSWR is high, this loss of delivered power shows up as periodic increases in insertion loss and causes the insertion loss vs. frequency curve to become discontinuous. The third cause of insertion loss non-uniformities is the use of a cable above its cutoff frequency. A coaxial assembly can provide its broadband performance because it propagates energy using a TEM mode, where both the electric and magnetic fields are perpendicular to the axis of propagation. As frequency increases, a point is reached where the half wavelength within the dielectric is equal to the mean circumference of the inner and outer conductors. At this frequency, and all higher frequencies, the coaxial system can support unwanted TE or TM modes. These resonances can cause sharp increases in the insertion loss at the frequencies where they are occurring that result in insertion loss “suckouts.” A typical example is shown in Figure 4.

Electrical length

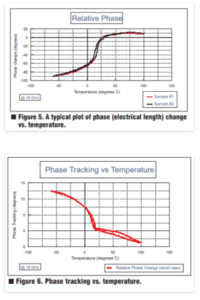

Many modern RF and microwave systems rely on signal phase properties to perform properly. Multi-element antennas can be quite sensitive to the phase or electrical length of the interconnects attached to them. It is common for a system designer to specify groups of cable assemblies to be provided in phase matched sets. Accurately matching a group of cable assemblies to within a few degrees at frequencies in excess of 18 GHz requires a degree of precision and processes exhibiting excellent repeatability. Just specifying an accurate initial phase match is not sufficient. The system designer must make sure the match survives while the assemblies are subjected to the rigors of the installation process.

If the cable assemblies will be subjected to high power levels, or if the assemblies will be flexed or subjected to a dynamic temperature environment, the designer should be very careful to adequately specify the environment along with the system phase requirements. Initial match is an important issue, but a phase sensitive system requires cable assemblies that remain matched. In other words, the electrical length of the assemblies must track each other as the environmental conditions fluctuate. Figure 6 presents phase tracking performance over temperature. In general, there are three methods that are used to specify phase matching. The most common of these is a group of two or more assemblies phase matched (or time delay matched) to each other. A group of assemblies specified in this manner would have to be replaced as a group in the event that any one assembly in the group were to undergo a failure. To avoid replacing a complete coaxial harness, only the highest quality, time-proven cable assemblies should be used.

If the cable assemblies will be subjected to high power levels, or if the assemblies will be flexed or subjected to a dynamic temperature environment, the designer should be very careful to adequately specify the environment along with the system phase requirements. Initial match is an important issue, but a phase sensitive system requires cable assemblies that remain matched. In other words, the electrical length of the assemblies must track each other as the environmental conditions fluctuate. Figure 6 presents phase tracking performance over temperature. In general, there are three methods that are used to specify phase matching. The most common of these is a group of two or more assemblies phase matched (or time delay matched) to each other. A group of assemblies specified in this manner would have to be replaced as a group in the event that any one assembly in the group were to undergo a failure. To avoid replacing a complete coaxial harness, only the highest quality, time-proven cable assemblies should be used.

Another method of matching cable assemblies is to maintain a “golden standard.” A golden standard is an assembly that is a duplicate of one of the assemblies in the phase matched set of cables that is installed into the system. This assembly is retained by the manufacturer. When a replacement assembly is required, it can be phase matched to the golden standard and thereby be matched to the associated assemblies in the field. This avoids the necessity to replace an entire run of phase matched cables when only one of the individual assemblies is damaged.

The third option when specifying phase matched cables is to specify an exact electrical length. This can be specified in units of degrees or as a time delay value. When a dynamic physical environment is anticipated, it is advantageous to have cable assemblies that will maintain their match when extremes of temperature are encountered. It can also be important that a cable be bent and flexed and that the group maintain its phase tracking characteristics.

With proper conductor, dielectric and connector choice and design, cable assemblies can be routinely produced that offer initial phase matches of less than 6 degrees at 18 GHz. These assemblies are able to track each other to within 18 degrees after being subjected to multiple flexes, tight bend radii and temperature extremes from –60°C to +125°C. These matching specifications can be maintained even when an individual set of assemblies is subjected to the torture tests contained in the most severe military qualification regimens.

Shielding effectiveness

Many applications require that system components be located in close proximity to other sensitive electronic instruments. Electromagnetic interference (EMI) is a fundamental issue concerning system performance, as well as the systems compatibility with other systems that may be located nearby. It is important that the shielding effectiveness be adequate to completely isolate the system’s signals from the environment. As signals are propagated through a coaxial cable assembly, electromagnetic waves come into contact with the shields. These EM fields, when contacting the shields, cause currents to flow that produce electric and magnetic fields. Where these fields contact the shield, fields are created in the shield conductor. The field density within the shield is highest on the inside of the shield and decreases to its minimum value on the outside of the shield. These fields closest to the outside of the shield are the fields that are radiated, or leaked, from the cable. These signals are the cause of EMI.

These fields tend to reinforce the propagated wave on the inside of the shield while canceling the propagated wave on the outside of the shield. The degree of this cancellation is measured as the attenuation of the signal as it passes through the shield. Shielding effectiveness is the ratio of energy inside the cable referenced to the energy radiated from the outside of the cable. There are several methods to measure shielding effectiveness of a cable. Two of the most common methods are transfer impedance and the resonant cavity method.

Transfer impedance is the characteristic of a cable’s shield that determines its shielding effectiveness. When the transfer impedance is very low, the magnitude of the E fields on the outside of the shield is lower. As the transfer impedance increases, these E field magnitudes increase proportionally.

A transfer impedance measurement is an accurate method for determining a cable’s shielding effectiveness up to approximately 100 MHz. This method is limited to measurement of the cable’s shield. It cannot test the connector interface or the connector-cable junction.

When a shielding effectiveness measurement is desired at frequencies from 2 to 18 GHz, a resonant cavity method is preferred. This method also allows for isolation of the root cause of an RF leakage to a specific area of the assembly. To perform this test, an assembly is placed longitudinally in a resonant, half wave coaxial cavity. The cable under test is then excited with a signal whose power level is known and whose frequency equals the resonant frequency of the cavity. The signal level inside the resonant cavity is sampled, compensated for the loaded Q of the cavity, and compared to the power level inside the assembly under test. The ratio of power inside the cavity referenced to the power inside the assembly is the assemblies’ shielding effectiveness. This method is used to characterize the cable shield, but it can also be used to characterize discrete components of a cable assembly. This provides a valuable tool in optimizing cable terminating techniques and interface methods.

To provide a shield having high shield attenuation, a relatively thick, homogenous metal should be used. This metal should be highly conductive and have low relative permeability. The best commonly available shield construction, from the standpoint of shielding effectiveness, is a solid copper tube. This construction has severe limitations in other areas, but it is largely regarded as the benchmark against which shielding effectiveness can be compared. A solid copper tube, because of the relatively thick wall, has a relatively large cross-sectional area. This area, in conjunction with its uniform structure, provides a low transfer impedance and a very effective shield. Unfortunately, this type of cable structure is limited in flexibility and the number of times that it can be bent. When these types of cable assemblies are specified, complex bend data also must be specified carefully, so that the cables will fit into their next higher assembly.

For this reason, many system designers opt for flexible cable assemblies. Common flexible cables typically use a braided wire shield. While it is possible to provide close to 100 percent optical coverage, the simple braid alone cannot provide shielding effectiveness as high as a solid metal shield.

To optimize shielding while maintaining a flexible cable construction, a combination of shielding techniques and materials are used. Strips of silver plated copper, round wire braids and metalized interlayers are used to provide coverage in excess of 100 percent, while maintaining a fully flexible, lightweight cable construction. Assemblies, when properly terminated, can easily provide shielding in excess of 100 dBc.

Environmental sealing

Quite often, a cable assembly is subjected to extremes of altitude, temperature and humidity, or a combination of any of these conditions. To ensure long life and flawless performance under these conditions, the assembly must maintain an impeccable vapor seal. The integrity of this seal must remain intact regardless of any physical abuse that may be inflicted on the assembly.

When a high performance assembly is manufactured, advanced Quality Assurance methods should be employed to ensure that the assembly is hermetically sealed. One of these methods is verify the seal using mass spectrometer methods.

To test an assembly this way, it is filled with a carefully calibrated 1 percent helium solute in a nitrogen solution. (as the final step during connector termination.) After the assembly is finished, it is placed in a vacuum chamber and the amount of the helium tracer is detected with a mass spectrometer. With this data, the leakage rate of the seal can be calculated. This helium leak test is valid for several days after the assembly has been backfilled.

If a significant amount of time has elapsed, or if the assembly has been in the field for a period of time, then other methods are required to test the seal of the assembly. Probably the best of these methods is the “Navy Leak Test,” specified as part of the military standard MIL-T- 81490. With the Navy Leak Test, the assembly is placed into an airtight chamber whose volume is accurately known. By careful analysis of the assembly geometry, its internal volume is also known, as well as its internal pressure (local atmospheric pressure). By evacuating the test chamber and measuring the gradual increase of the chamber pressure, the leak rate of the assembly can be calculated.

Proper design and assembly techniques can provide flexible cable assemblies with leakage rates less than 1 ´ 10–5 cc/sec/ft of assembly length. With sealing rates this low an assembly is impervious to contaminant ingress that commonly occurs in installations where immersion or soaking in deicing fluids or petrochemical fluids is occurring.

Subscribe to our newsletter!

Interested in receiving email newsletters and other updates from Times? Subscribe now!